This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

EMEA & APAC AWARDS • THE AMERICAS AWARDS

The Dome: Miami

ProjectThe Dome: MiamiLocationMiami, FloridaManufacturersVIOSO America, USA - Digital Projection, USA - Broadwell Air Domes, USADistributorLumen & ForgeInstallerLumen & ForgeSubmitted byVIOSO

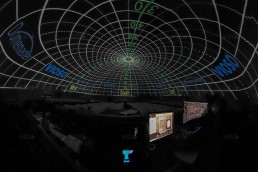

The largest sporting event in the world garnered the largest projection dome in the world. Located just outside Super Bowl LIV in Miami, Florida, a 225 ft x 175 ft Broadwell inflatable dome was erected for some of the largest R&B and HipHop names and events. Lumen & Forge was tasked with projection mapping the 40,000 sq ft of projection surface using 24 Digital Projection M-Vision Laser 18k projectors. Together with VIOSO, it auto-calibrated the entire dome surface for mapping in a matter of an hour for a complete seamless image across the entire dome surface. With a custom Domemaster playback server, content was served as two 4K @60Hz feeds. The custom content was created by Lumen & Forge to be mapped on the dome as the unique ‘pill’ shape of the dome is very different than a standard hemispherical shape found at most venues. Since this installation was used for concerts and events, traditional media and videos wouldn’t have sufficed. Instead, the Lumen & Forge Domemaster server was used with VIOSO’s Blackbox software to perform the calibration and provide the warping and blending, which was then fed by the Lumen & Forge Mediaserver through the capture cards.

While many industry standard projection domes have a hemispherical shape, the one implemented for this project boasted a uniquely oval, or ‘pill’, shape. Created by Broadwell Air Domes USA, the colossal size of the structure was decided due to the use of the dome, which would host concerts and parties within: The pill shape would also allow for a higher capacity of visitors, while creating optimal placement for the 24 Digital Projection M-Vision Laser 18K projectors installed inside, in order to project the content on the inside without any interference or view restriction.

While advantageous from a capacity perspective, the unique shape had major bearings on both camera calibration and content creation. After designing the dome in a 3D space, Lumen & Forge was able to develop content that was placed into VR for testing. Using this method, the 16×9 content was modified to fit the shape of the dome. The standard circular or ‘domemaster’ format for typical domes would have been severely distorted if used, so a customised format was created.

The shape of the dome didn’t end with the content but offered its own inherent challenges with the calibration. Using a camera calibration system was necessary for the time constraints the team was against. Unfortunately, they don’t make an oval camera lens, so it had to move forward with the standard fisheye. Calibrating the dome with the fisheye lens created a final compound in this round format, however, using that same UV texture map that was created for the content production proved the solution here as well. VIOSO simply used the UV texture in its conversion format, with a little extra algorithmic math, and it was able to perfectly fit the compound to the ‘pill’ shaped dome without distortion or issues.

Creating solutions is something that all teams involved are exceedingly specialised at doing. The teams only had two months to design the projection study and specify the technical aspects, and by the set up time in late January, the construction of the dome was already ongoing and time was not on the team’s side. This meant that the team’s first opportunity to operate the calibration was a mere three days before opening. It could also only take place at night, as the field operations team was still completing the dome’s construction.

Every evening, the dome was about one or two metres larger, making the calibration from the previous evening unusable. The relentless passion and efforts of the on-site teams made sure that this project was not only a success, but a feat of magnificence that would be used as a reference for projects to come. Many late nights were spent to be sure that all aspects were not only sufficient to the client, but were becoming precedents to the industry. This included flying in the development engineer from Germany to make sure that our math was not only correct on paper but also in real life. The dome was organic and dynamic, it was not a hard structure so it was impacted by the elements, environment, and even the temperature.

The teams only had one night for the final calibration, in which the size, scope and shape of the dome would again need to be reconsidered. By that final evening, we had expertly learned what worked with the live calibration and we perfected the ‘less than an hour’ full dome calibration. A huge success for all involved and an accomplishment for the ‘Worlds Largest Projection Dome’.